Different Types of Denim Wash :

After pre-treatment, denim garments may be subjected to different types of wash. Some of commonly used

wash types are:

- Stone Wash

- Acid Wash

- Rinse Wash

- Enzyme Wash

- Bleach Wash

Stone Wash : This is the most common and basic process for producing a washed-down look on denim garments.

Towards the end of the seventies, pumice stones were discovered to accelerate the ageing process of

the indigo dyed denim garments.

Acid Wash (Moon Wash) : Acid washing or ice washing is usually done by tumbling the garments with pumice stones presoaked in

an acid solution, such that localized bleaching is effected in a non-uniform sharp blue/white contrast in

the garment.

Rinse Wash (Mill Wash) : The objective of the rinse washing is to keep the fabric appearance as dark as possible. The denim is

desized width-wise in open-width washing machine and the dye is not washed out.

Enzyme Wash : As denim is made of cotton, it too consists of cellulose. Celluloses can be used to give denim a worn

look. Enzymes have opened up new possibilities in denim finishing by increasing the variety of finishes

available. For example, it is now possible to fade denim to a greater degree without running the risk of

damaging the garment. Cellulases are the enzymes commonly used in enzyme wash. As the name

suggests, it degrades cellulose.

PIONEER

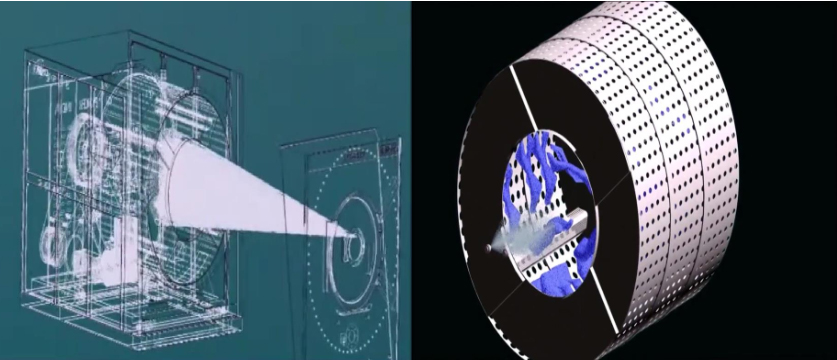

TM DRIZZLE JET ECO-FLOW Technology uses micronization and

nebulization techniquies to eliminate the traditional abrasion processes and delivering better performance

chemistry (color, softeners, antimicrobials, etc.) by using nanobubbles of air instead of water. "PIONEER" DRIZZLE

JET ECO-FLOW provides great versatility to finishing processes, reducing the cost of application, saving the amount

of water used and ensuring that the correct amount of chemicals stays in the garment and not in the water.

Basically, the technology and working principle behind the PIONEER

TM DRIZZLE JET ECO-FLOW is the formation of

nanobubbles of air enveloped by concentrated mixture of water and chemicals, and that mist form of water and

chemicals are to be sprayed on garments for easy absorption, and PIONEER

TM DRIZZLE JET ECO-FLOW sprays the

mist in a uniform manner throughout the entire drum.

Micronization: Micronization refers to particle size reduction processes that result in particles size reduction in microns level.

So basically, due to this process, PIONEER

TM DRIZZLE JET ECO-FLOW able to create very small diameter

bubbles contain chemical without any notable dilution with negligible amount of water as bubble envelops.

Nebulization: Nebulization process can be explain as a process of creating a mist out of liquid (water + chemicals), allowing

the garments, a quicker and easier absorption of chemicals in an effective manner.